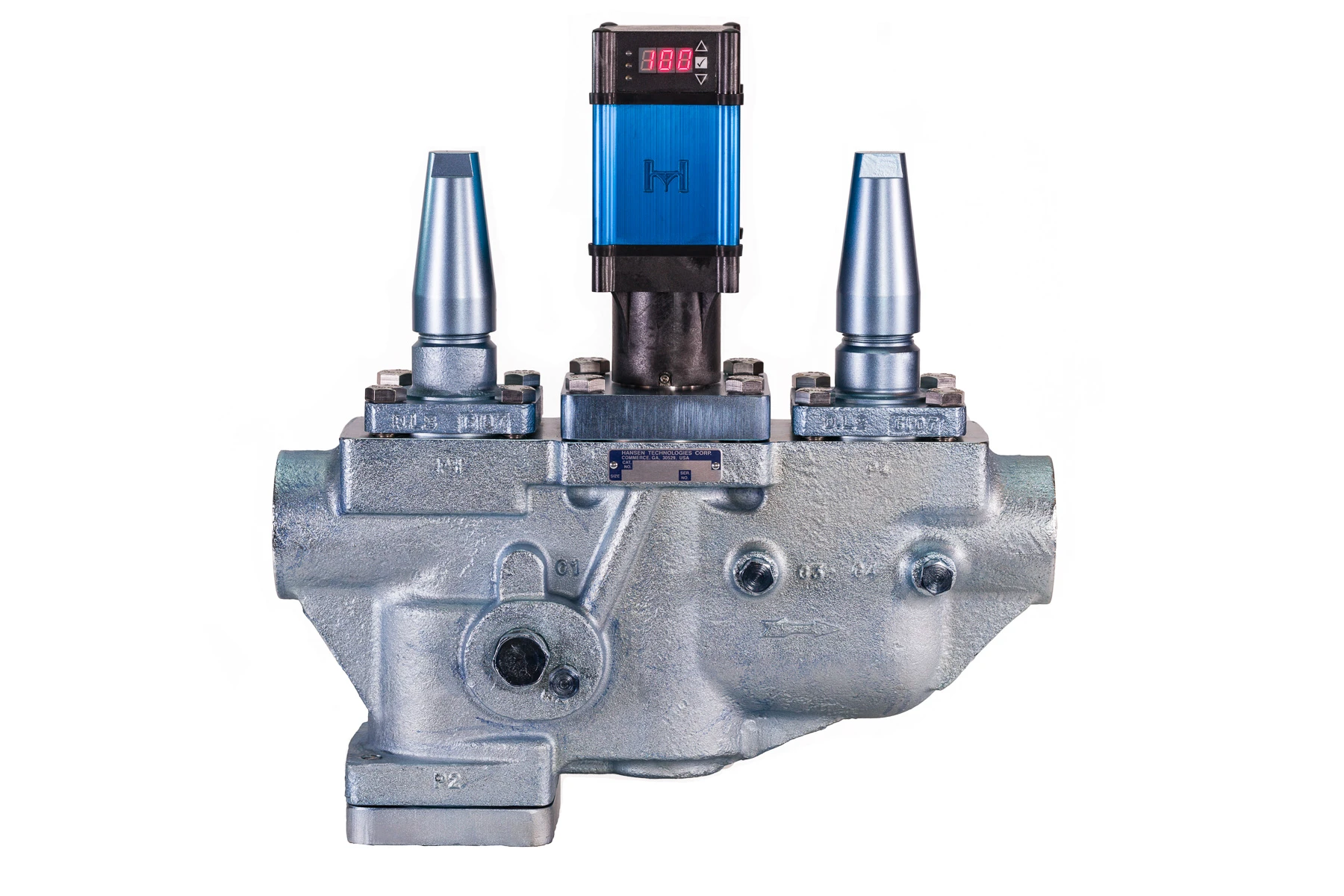

Hansen Technologies is an American manufacturer of high-quality components for industrial refrigeration. The company specializes in refrigeration components such as solenoid valves, control valves, and purgers. These products are primarily used in NH3 systems, where reliability and precision are essential.